As you can guess from our name, we at IPS Perforating, Inc. are experts in all things perforation. One of the many services we offer is micro-perforating, in which we take a material (such as leather, vinyl, or even wood veneer) and pierce it with numerous tiny holes across its surface. In this article, we will go over the basics of how micro-perforation works and what purpose it serves so that you can decide if it’s right for you.

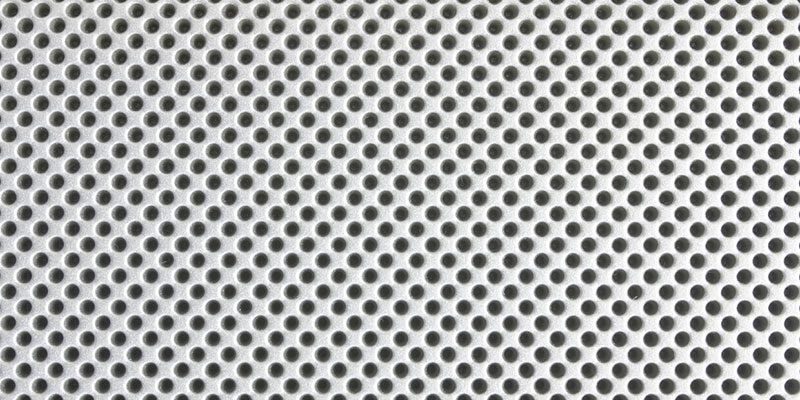

- Mechanics of Micro-Perforation. When a material is micro-perforated, it means that many submillimeter holes are punched into or dug out of its surface. These holes typically max out at just 0.6 mm in size, and they are applied across the whole expanse of the panel, clustered so densely that a single square foot of material can contain up to 30,000 micro-perforations.

- Effect of Micro-Perforation. What is the point of all these holes, though? To understand that, you need to know the basics of how sound waves work. When a speaker, instrument, or set of vocal cords vibrates, it causes the air to compress. When the sound wave hits a hard surface, the energy stored in the compressed air reflects back, causing the wave to bounce away and continue transmitting sound. When a sound wave hits a surface that has been micro-perforated, however, that compressed air is essentially absorbed into the perforations, causing the sound wave to lose energy and deteriorate rather than keep echoing through the room. This has the effect of dampening the sound and preventing the space from becoming too loud.